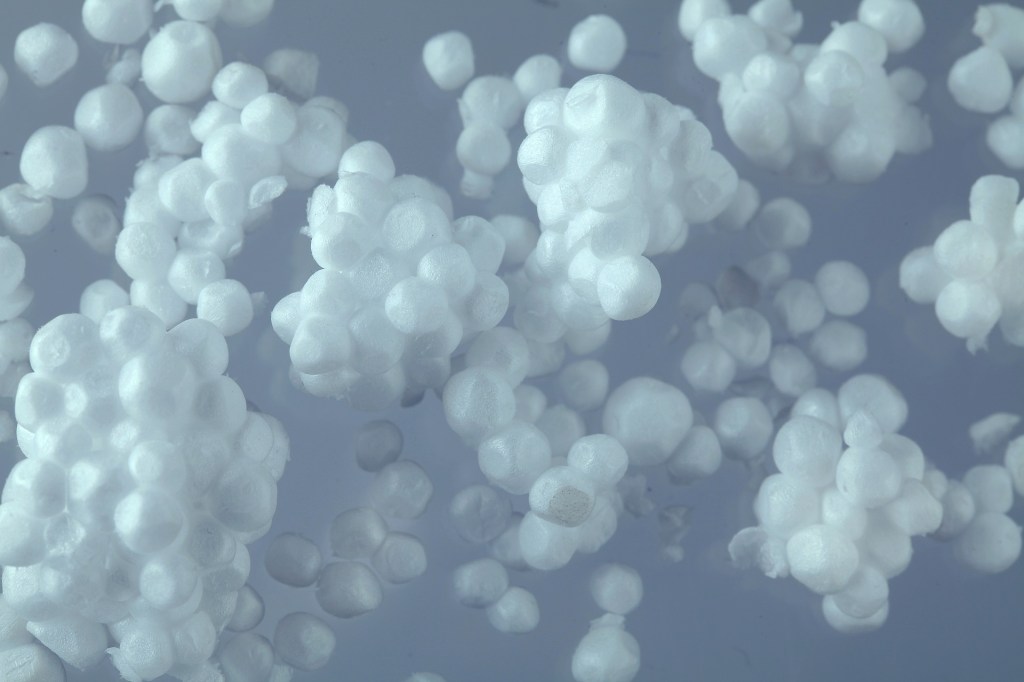

PS Resin (Polystyrene), utilizing the techniques from FINA in USA developed improved techniques in producing the major ingredients come from naphtha cracking project, this will ensure the stability of quality with competitive price.

GPPS & HIPS

PS Resin diversification contains general purpose (GPPS), which is crystal and easy processing and high impact (HIPS) that has low Gel and residual monomer. All production facilities are operated in accordance with strict environmental protection regulation and non-polluting the environment concerns.

Acrylonitrile Butadiene Styewne – ABS

ABS Resin product diversification contains general purpose, extrusion, jet black, high flow, heat resistance, flame retardant, transparent and metal plating that can fulfill the needs of. All production facilities are operated in accordance with strict environmental protection regulation, and waste gases treated by high-heat combustion, then heat recovered.

Acrylonitrile Styrene Acrylate – ASA

ASA Resin has excellent weather resistance and a stain ability. Production process fully by existing ABS devices to convert capacity adjusts supply to meet market demand. The major ingredients naphtha cracking project, and factory has lab and testing equipment, product development can be based on market demand, in addition to the general purpose and high flow grade, developing of building materials and automotive in response to the environmental protection and new energy material. The future product development will gradually replace specialty ABS, to comply with the environmental protection technology of spraying and electroplating.